Grain direction bend line should go across the grain for the best bend having said that a typical sharp 90 bend on a piece of 1 8 aluminum sheet should be a minimum 1 8 inside radius use either 3003 or 5052 ideally the bend line should go across the grain.

Which type of aluminum sheet bends best.

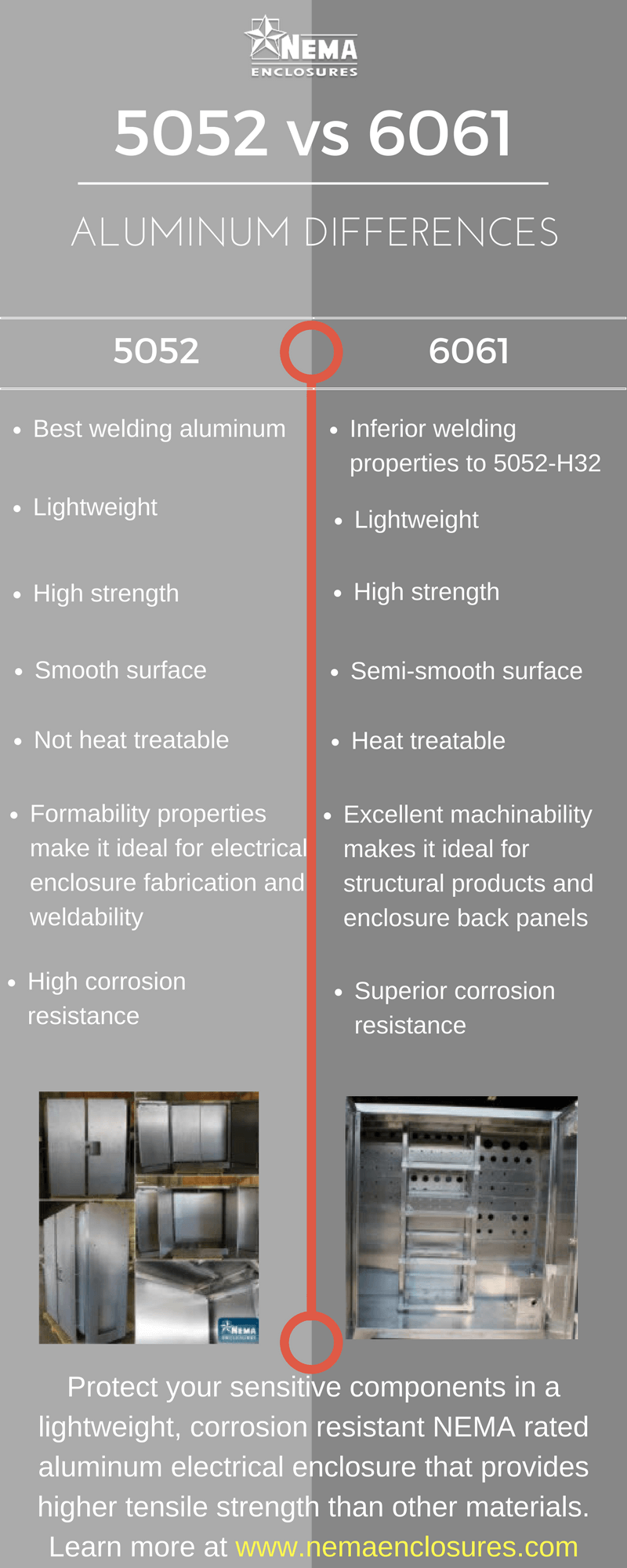

For example if weldability is most important to your project but strength is not it may make sense to choose alloy 1100 as this aluminum grade has excellent weldability but is not typically used for high strength or high pressure applications.

6061 t6 aluminum is tempered and notorious for not bending easily.

The top 3 aluminum alloys for being are the 3003 which has medium strength and the best cold workability the 5052 which is the highest strength alloy of the more common non heat treatable grades and the 6061 which is one of the more versatile heat treatable alloys.

Series 6xxx are the aluminum magnesium silicon alloys.

Series 7xxx are the aluminum zinc magnesium and aluminum zinc copper alloys.

This will give you a nice bend.

That s the ideal anyway but the reality is that many parts arrive at the press brake in a less than ideal state.

These heat treatable alloys exhibit great strength good corrosion resistance and ease of formability.

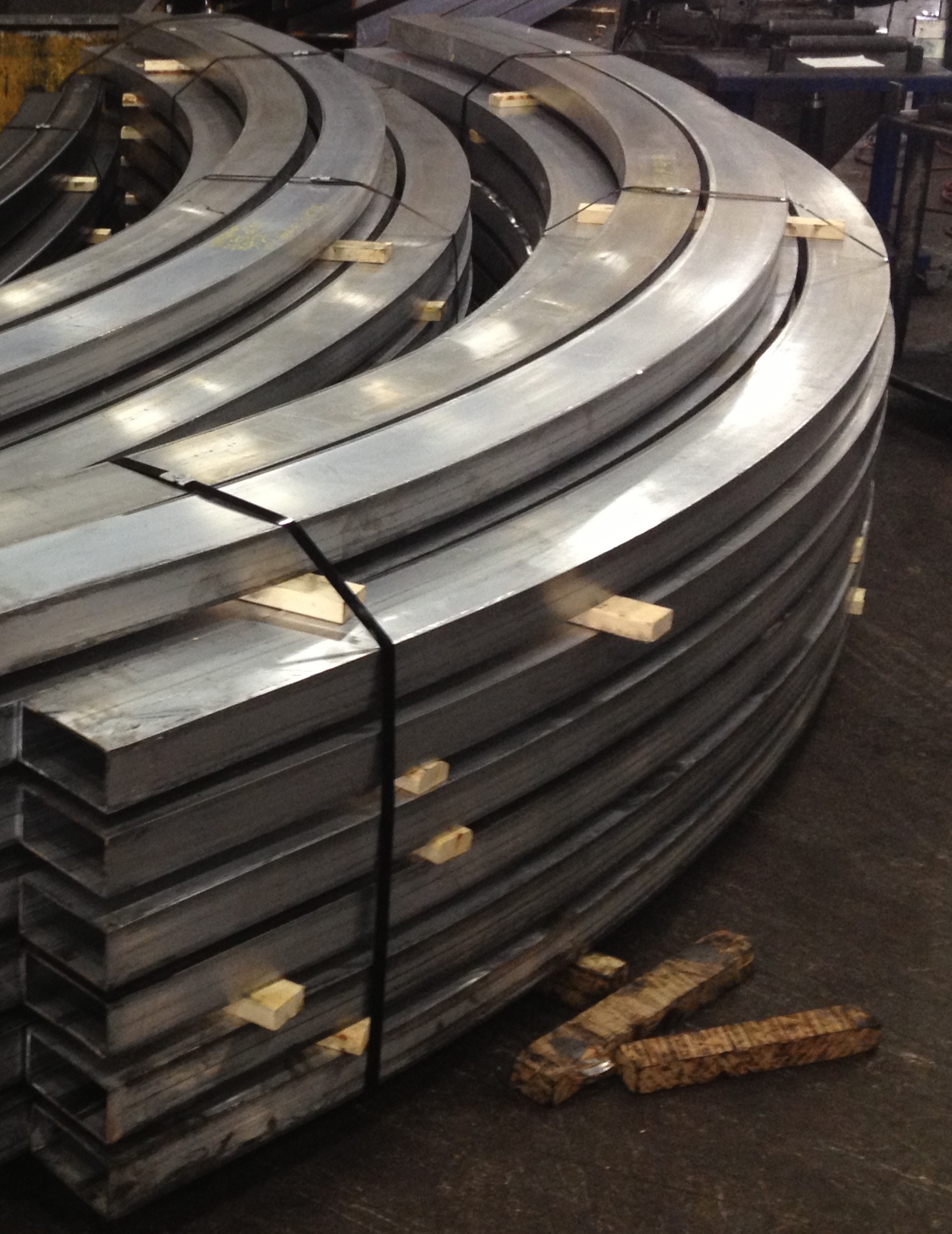

Heavy gauge aluminum bars or rods must be heat bent using an acetylene torch and vice.

A bending brake will be best suited for shaping flat square sheets of light gauge aluminum.

Miserable to bend cracking is very common and cold bending will always weaken the metal.

Aluminium alloy 6063 is a good choice for example while 6082 is more difficult.

Highly formable and one of the best kinds of aluminum to bend.

Basic bending brakes typically retail for around 20 50 and are small enough to fit easily on most work benches or tabletops.

The are mainly used in architectural applications.

The best aluminum alloys for bending come down to series 3xxx and series 5xxx and sometimes series 6xxx.

From a bending perspective it s always best to bend these parts in an annealed state and then temper them to the correct condition.

Proper bending can be done with annealing the aluminum first although it s not an ideal candidate for formed parts.

The most widely used of all aluminum alloys.

They exhibit very high strength making them very difficult to form.